光学三维计量学的实践

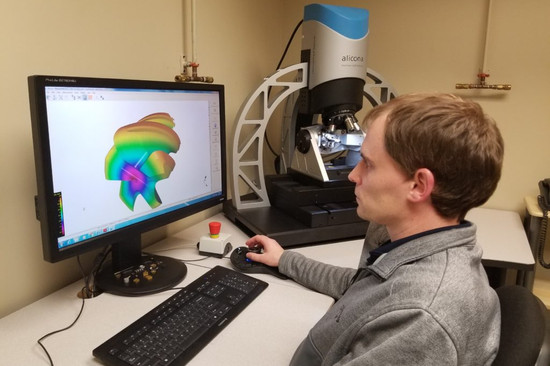

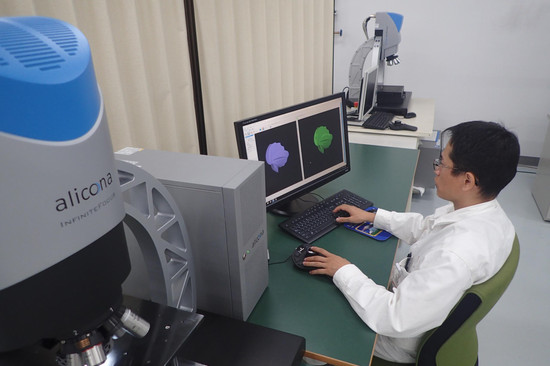

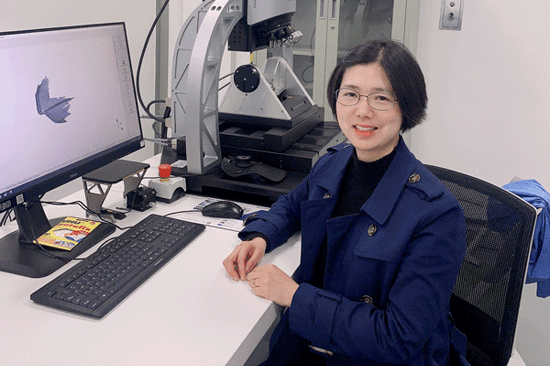

在这里可以找到最新的用户案例,了解更多关于Bruker Alicona的测量解决方案。我们的客户描述了他们如何使用我们的光学三维测量解决方案来保证质量。在各个领域的日常应用创造了额外的好处,你也可以通过使用Focus Variation技术来体验。

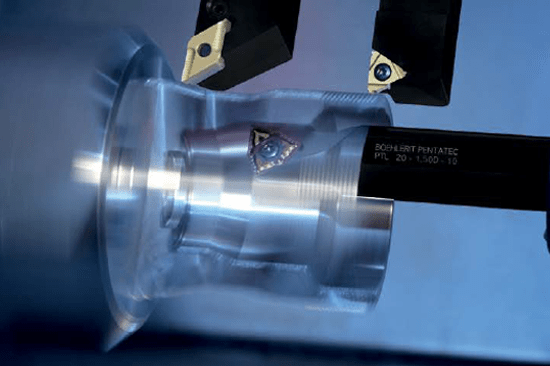

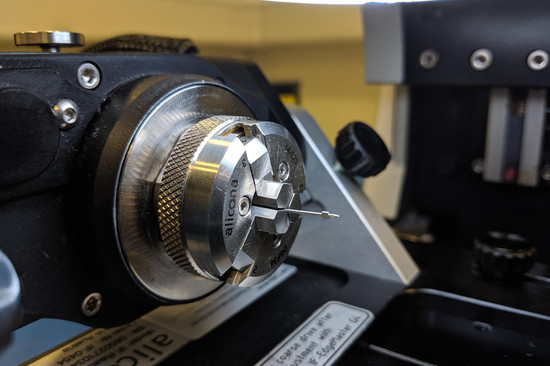

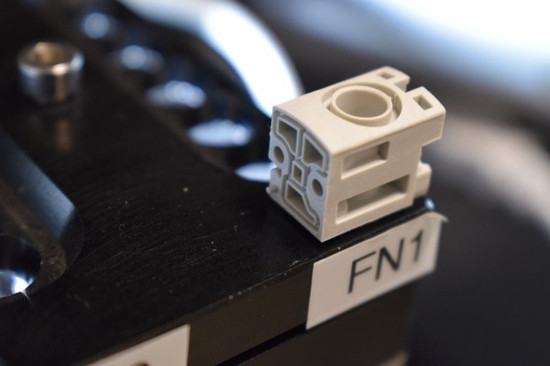

The biggest challenges we face are in quality assurance for the smallest components. These are less than ten millimetres. In addition, we work with titanium, a highly reflective material, which makes measurement particularly complex.

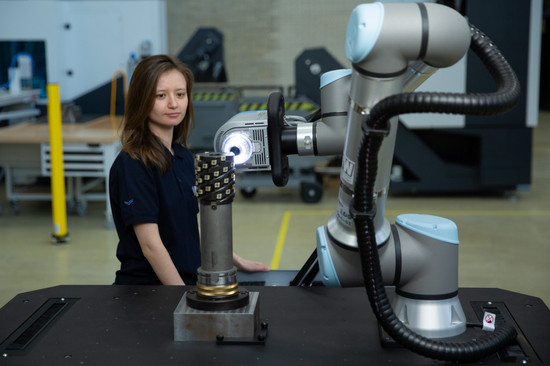

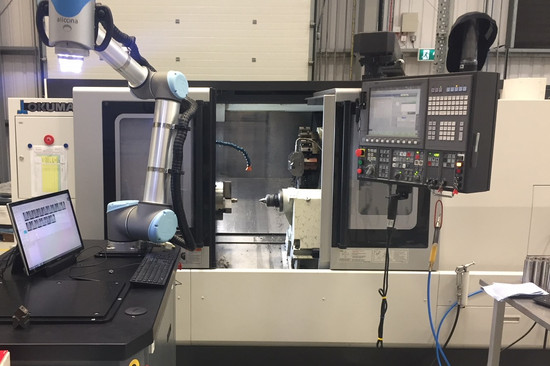

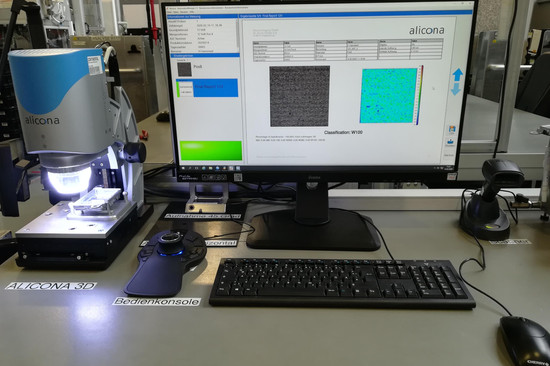

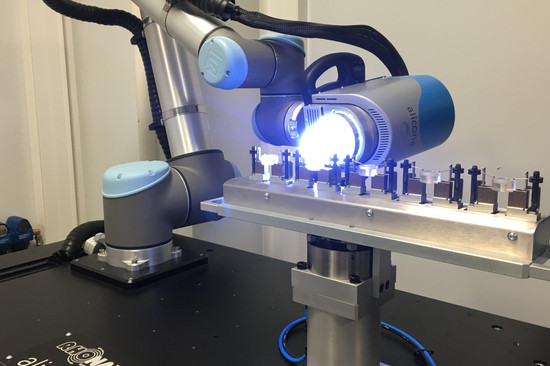

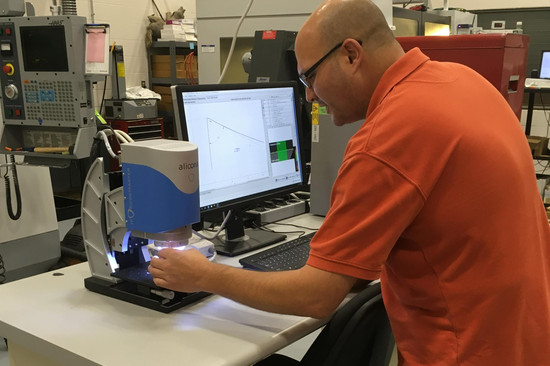

Using optical measurement technology we are faster, more accurate and, above all, process-capable. With Bruker Alicona we can also measure automatically in a CNC process.

If the workpiece material is optically cooperative and undercuts are not considered reasons for exclusion, Focus-Variation offers non-contact, two-dimensional measurement recordings with high measurement point density.

With Bruker Alicona, we can effortlessly measure geometric features that are difficult to access with other methods. Even the steep flanks and small geometries of the valve seats are no obstacle, unlike other measuring equipment. Form and position tolerances can also be easily verified.