Metrologia ottica 3D in pratica

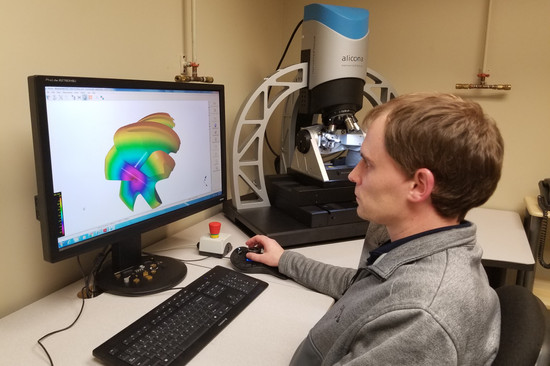

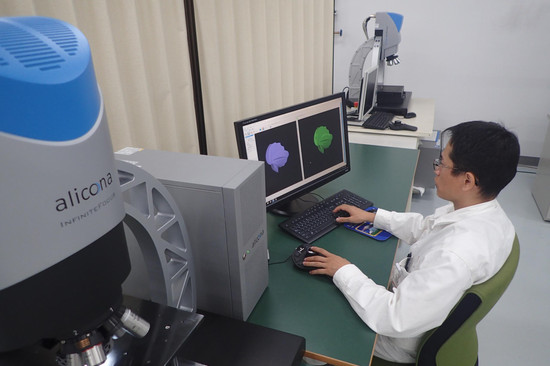

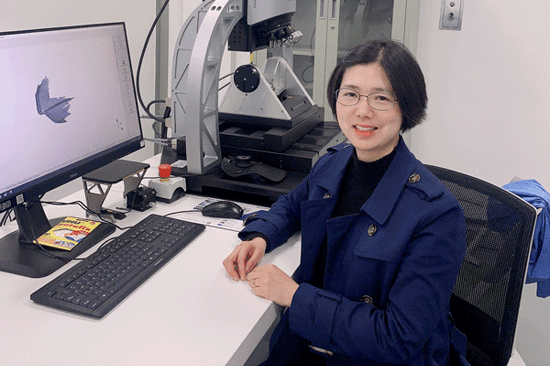

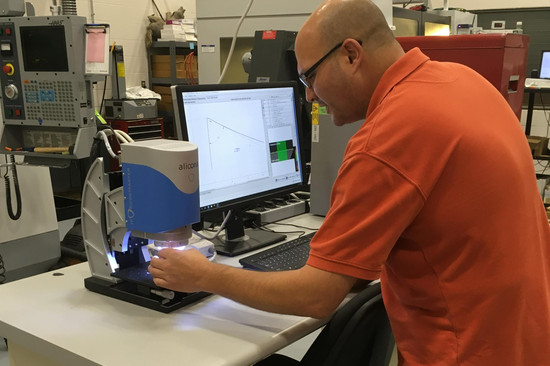

Trovate qui le ultime storie di utenti e scoprite di più sulle soluzioni di misura di Bruker Alicona. I nostri clienti descrivono il modo in cui utilizzano le nostre soluzioni di misura ottica 3D per il controllo qualità. Le applicazioni che si trovano quotidianamente in vari campi creano ulteriori vantaggi che anche voi potrete sperimentare utilizzando la tecnologia Focus Variation.

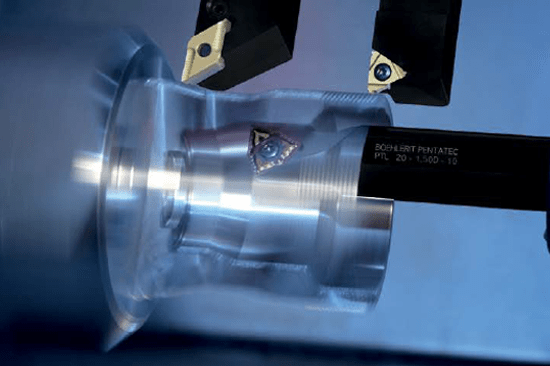

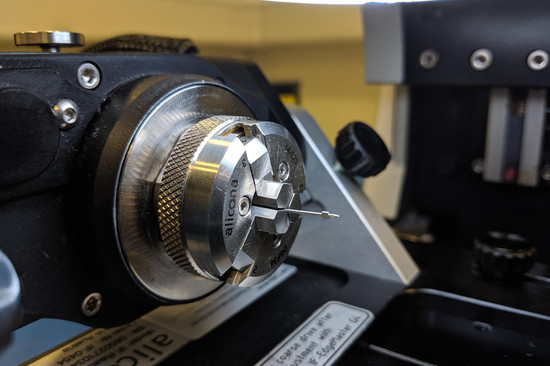

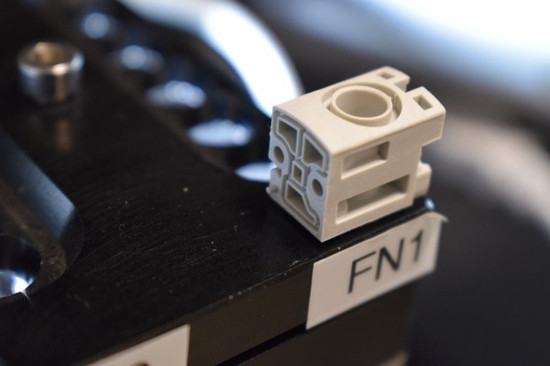

The biggest challenges we face are in quality assurance for the smallest components. These are less than ten millimetres. In addition, we work with titanium, a highly reflective material, which makes measurement particularly complex.

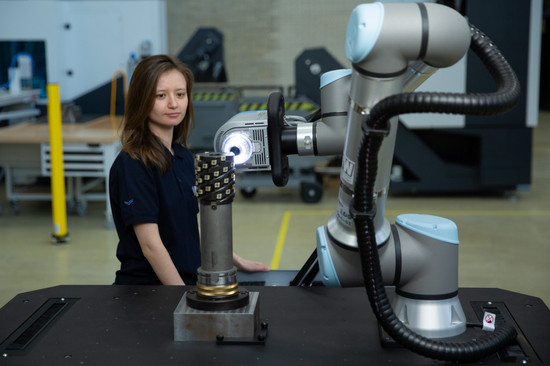

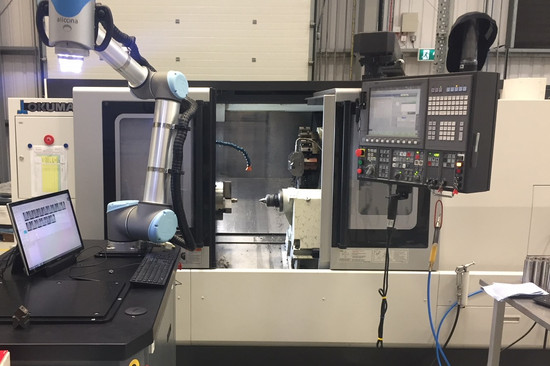

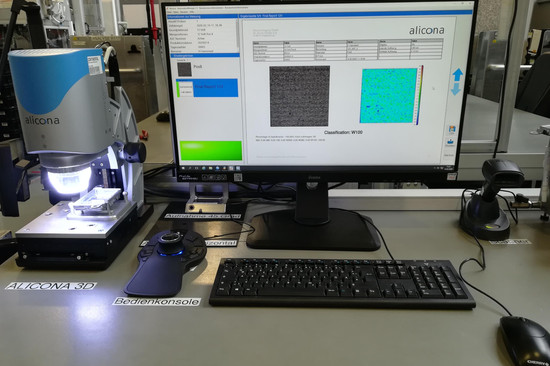

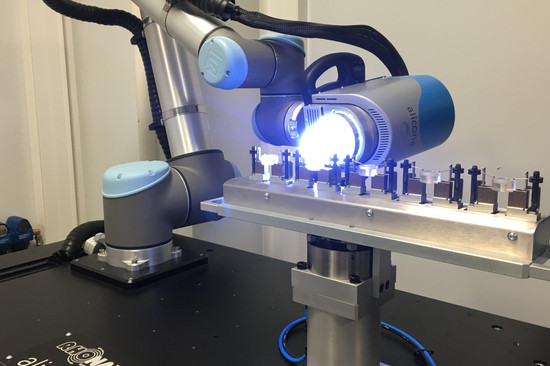

Using optical measurement technology we are faster, more accurate and, above all, process-capable. With Bruker Alicona we can also measure automatically in a CNC process.

If the workpiece material is optically cooperative and undercuts are not considered reasons for exclusion, Focus-Variation offers non-contact, two-dimensional measurement recordings with high measurement point density.

With Bruker Alicona, we can effortlessly measure geometric features that are difficult to access with other methods. Even the steep flanks and small geometries of the valve seats are no obstacle, unlike other measuring equipment. Form and position tolerances can also be easily verified.