Optical 3D metrology in practice

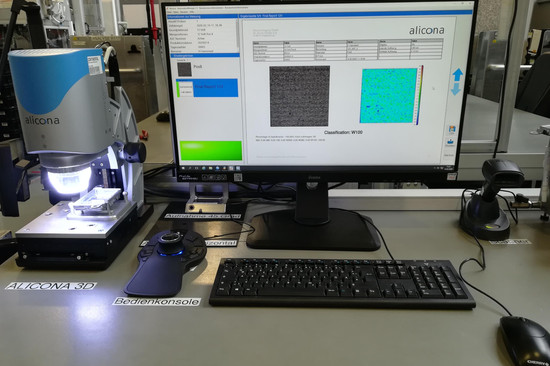

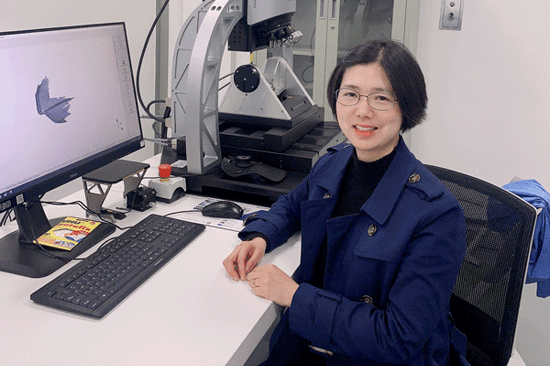

Find here the latest user case stories (success stories) and learn more about Bruker Alicona‘s optical measuring solutions. Our customers describe the way they use our optical 3D measuring solutions for quality assurance purposes. The applications found daily in various fields create additional benefits that you too can experience from using Focus Variation technology.

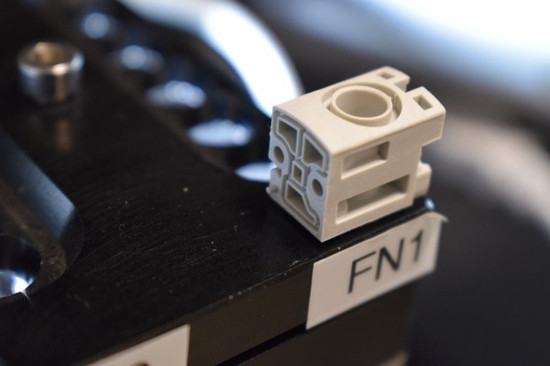

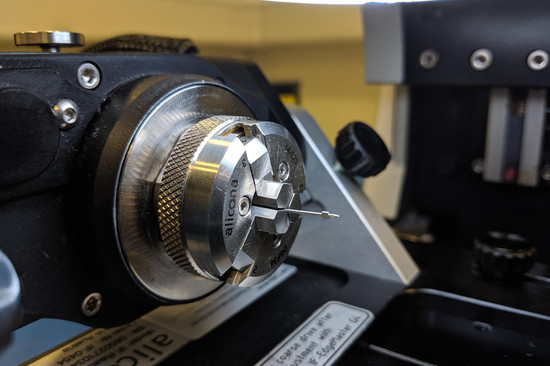

The biggest challenges we face are in quality assurance for the smallest components. These are less than ten millimetres. In addition, we work with titanium, a highly reflective material, which makes measurement particularly complex.

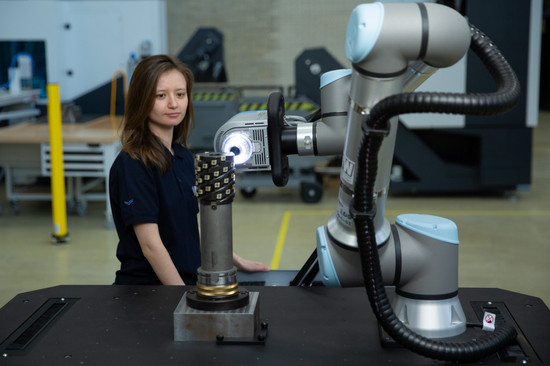

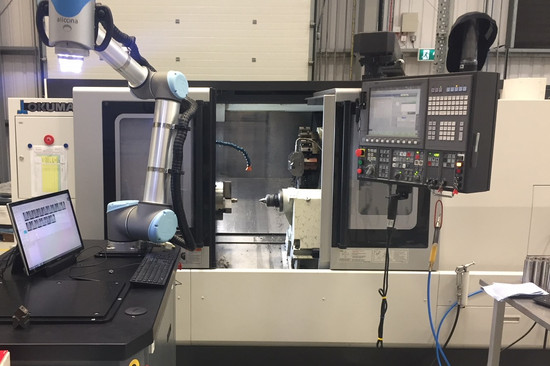

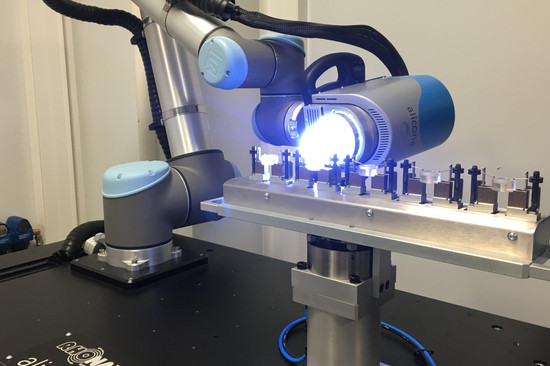

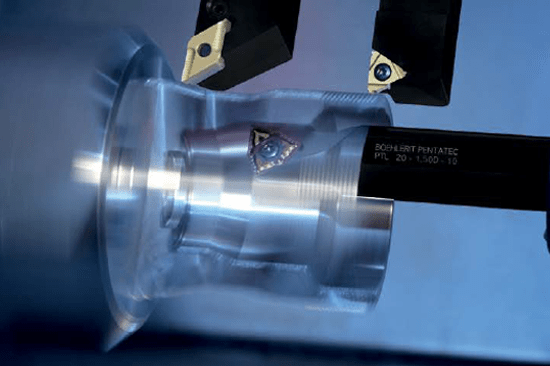

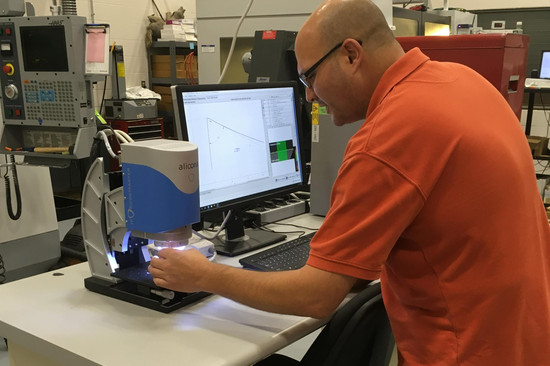

Using optical measurement technology we are faster, more accurate and, above all, process-capable. With Bruker Alicona we can also measure automatically in a CNC process.

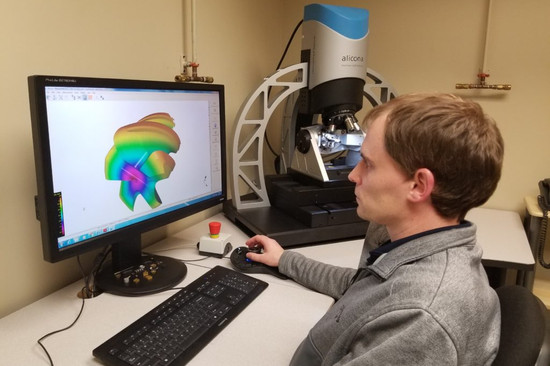

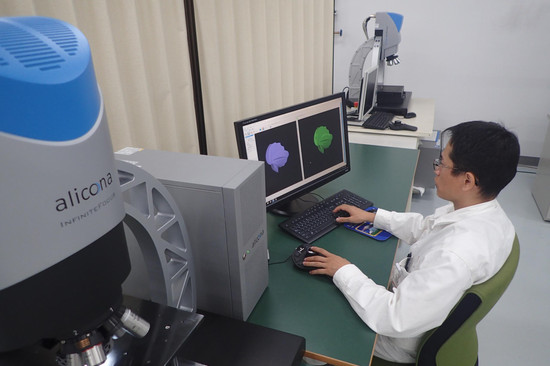

If the workpiece material is optically cooperative and undercuts are not considered reasons for exclusion, Focus-Variation offers non-contact, two-dimensional measurement recordings with high measurement point density.

With Bruker Alicona, we can effortlessly measure geometric features that are difficult to access with other methods. Even the steep flanks and small geometries of the valve seats are no obstacle, unlike other measuring equipment. Form and position tolerances can also be easily verified.