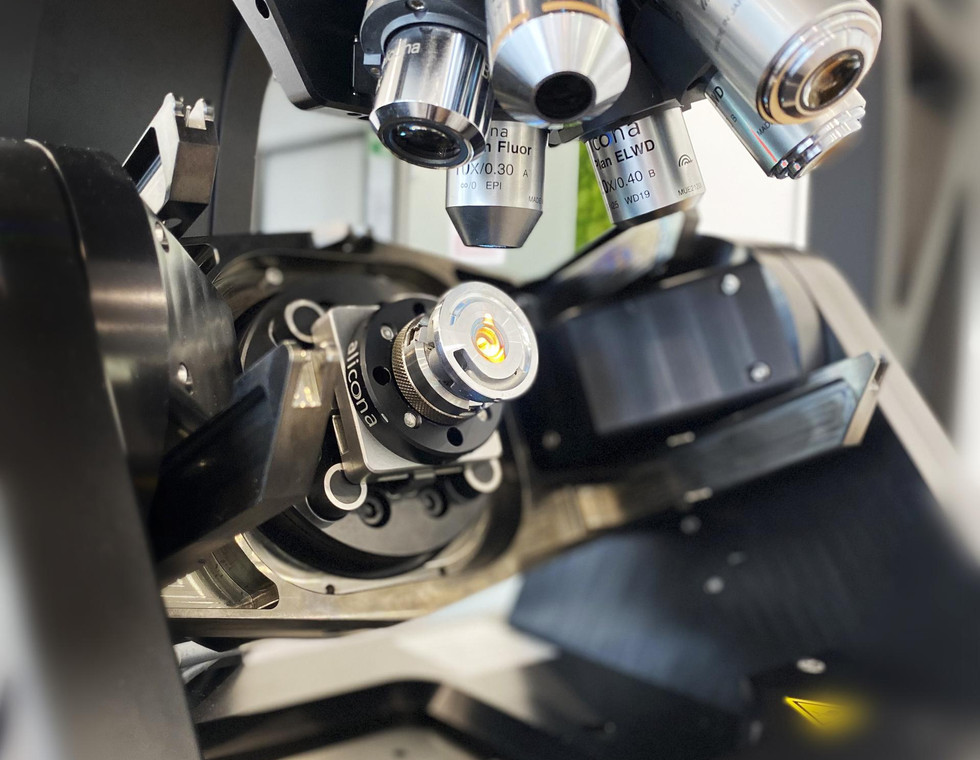

非接触式形状和粗糙度测量技术

您是否正在寻找一种非接触式测量解决方案,用一个传感器测量形状和粗糙度,横向探测部件,从而测量超过 90° 的垂直侧面?此外,您还希望对单个部件进行更快速、自动化、可重复和可追踪的测量?那您就来对地方了。

为什么选择光学计量?

光学计量的优势显而易见:

与在表面上滑动的探针可能造成损伤不同,无接触测量的部件完全不会受到损害。传统的粗糙度测量系统由于探针直径的限制,难以测量狭窄的沟槽,而光学测量设备则能够精确捕捉表面上最微小的深度。

dieSonne-(3)-659x439.jpg)

为什么选择非接触式测量?

非接触式测量的优势显而易见:探头在表面上移动可能会造成损坏,而非接触式测量的部件则完全不会损坏。触觉粗糙度测量系统在测量特别狭窄的沟谷时会受到探头直径的限制。而非接触式测量设备则可以准确地显示表面最细微的深度。此外,只有非接触式测量设备才能在合理的时间和资金范围内进行面积测量。布鲁克-爱丽科纳公司的以下技术使非接触式形状和粗糙度测量成为可能:

光学计量的优势

- 使用一个光学传感器即可测量尺寸、位置、形状和粗糙度

- 可测量垂直表面 > 90°

- 对关键部件进行快速测量

- 即使在大测量体积下也能测量小半径和角度

- 可应对陡峭侧面及具有不同反射特性的部件(如抛光、光亮表面)

- 适用于具有不同表面处理或涂层的部件

- 支持基于轮廓和区域的表面粗糙度参数

- 软件易于使用,处理速度快,测量结果精准

- 实现完整形状测量

dieSonne-107-659x439.jpg)