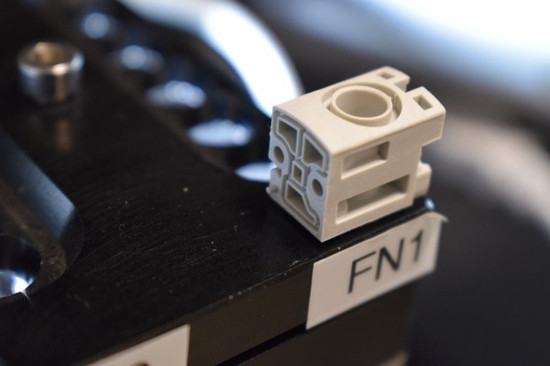

La métrologie optique 3D en pratique

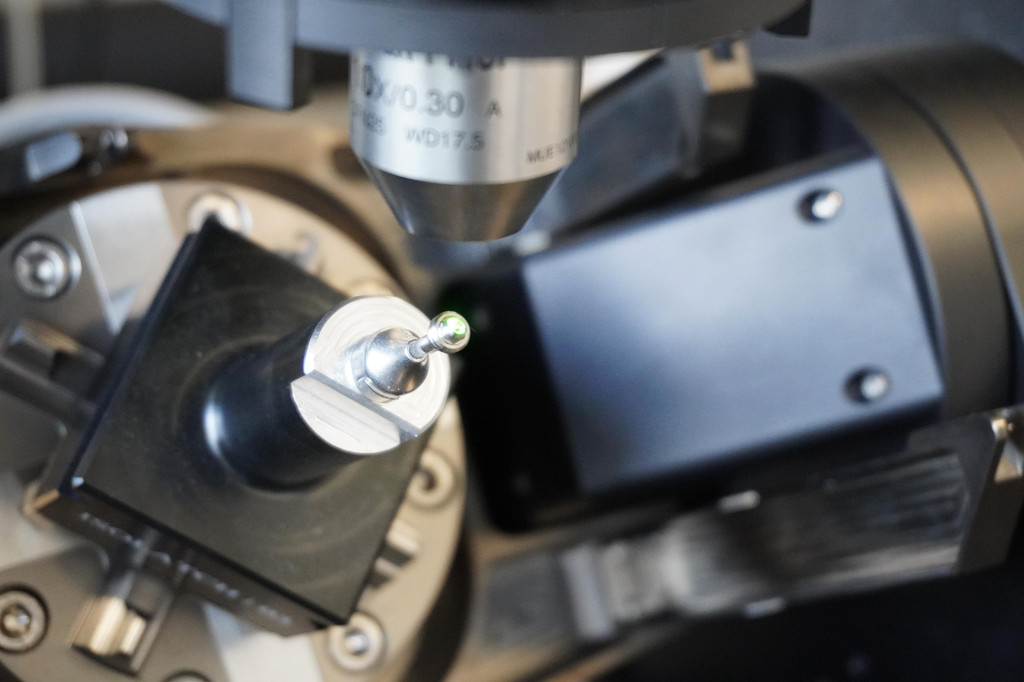

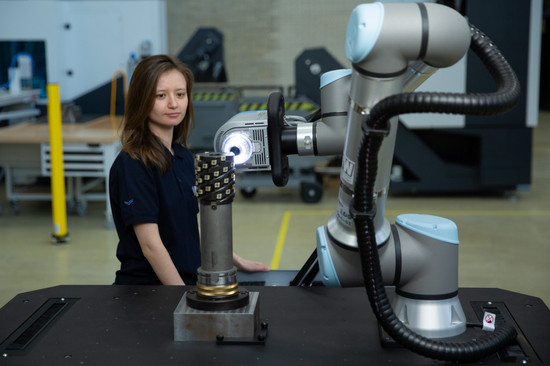

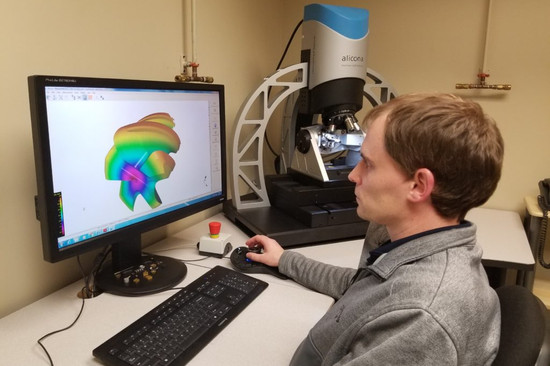

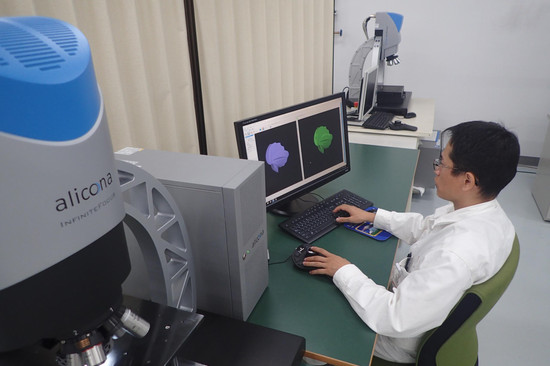

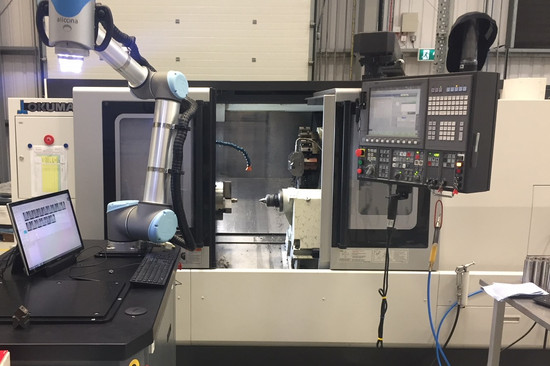

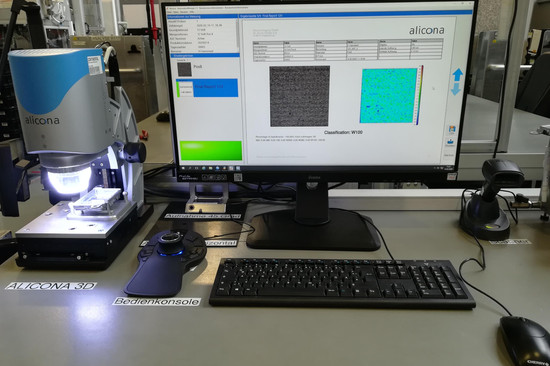

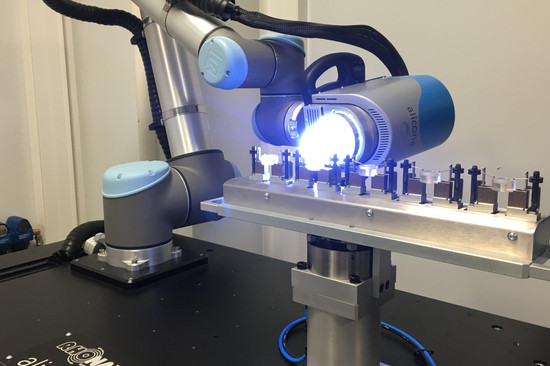

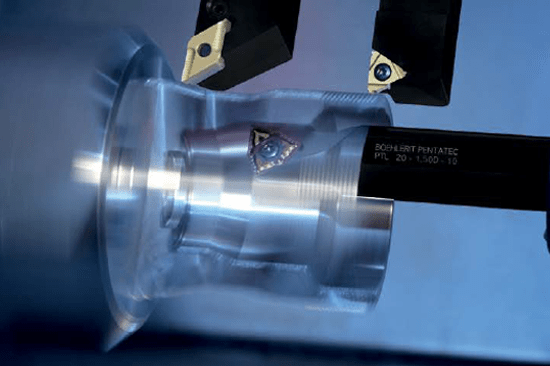

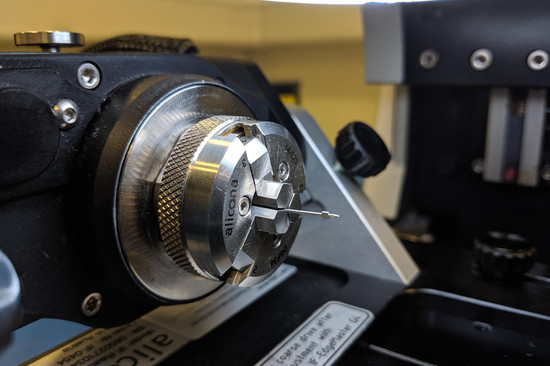

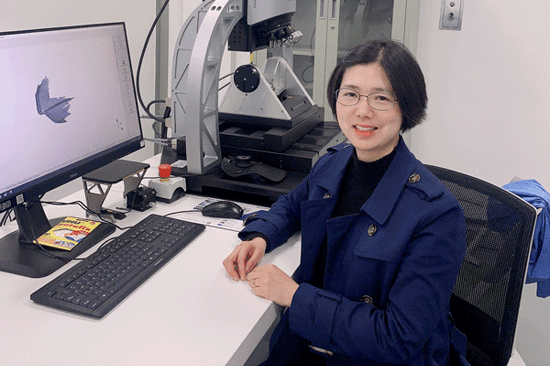

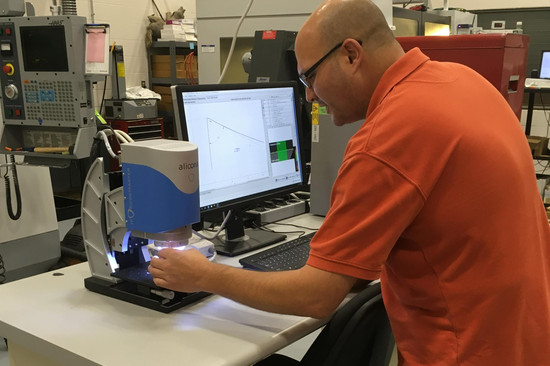

Découvrez ici les derniers témoignages d'utilisateurs et apprenez-en plus sur les solutions de mesure de Bruker Alicona. Nos clients décrivent la façon dont ils utilisent nos solutions de mesure optique 3D à des fins d'assurance qualité. Les applications trouvées quotidiennement dans divers domaines créent des avantages supplémentaires que vous pouvez vous aussi expérimenter en utilisant la technologie Focus Variation.