Blog

测量系统分析(MSA)是计量界的一个核心因素,因为它决定了一台仪器完成测量任务的能力。

In production measurement technology, a measurement process analysis (MPA) or measurement system analysis (MSA) has to be carried out. MPAs or MSAs are useful to determine the accuracy of measurements in an experimental set-up and to assess measurement quality by making sure the measuring instrument is capable of completing the measurement task adequately and accurately.

There are different methods which can be used to determine the capability of the measuring equipment and the measuring process under real operating conditions – by means of repeated measurements based on standards or real samples, and with or without user influence. In general, these procedures are also known as Gage R&R (Repeatability & Reproducibility) methods. Different industry standards imply varying numbers of measurements, users, parts, repetitions and limits.

Cg and Cgk values define the measurement process capability, which is determined by analyzing the standard deviation/precision and the bias/trueness of a measurement system. Usually, a measurement system must have a measurement process capability Cg, Cgk > T, with T varying depending on the industry, company or component. The larger Cgk, the more capable the instrument – here is the mathematical formula behind it:

T ... 图纸上的公差

S ... 测量的标准偏差

xg- xm.... 相对于参考值的测量偏差

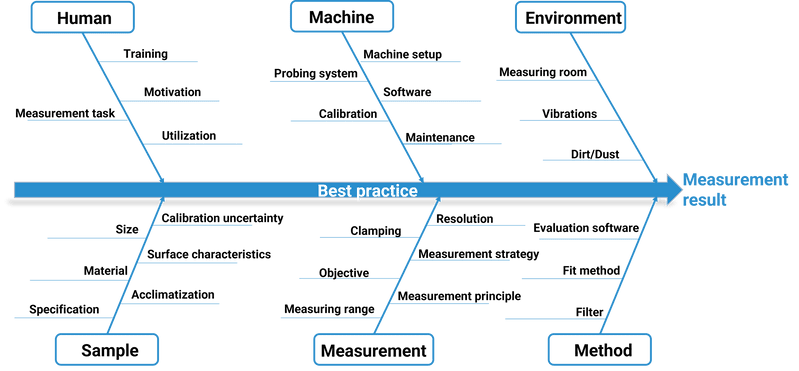

在实践中,也应减少影响因素--如人为因素、测量设备或环境--。在这里可以看到所谓的石川图: