The Coordinate Measuring Machine CMM for High-Precision Manufacturing

Experience the revolution in manufacturing metrology with the µCMM, the first purely optical CMM machine. This state-of-the-art optical coordinate measuring machine combines unparalleled precision with user-friendliness, elevating your production quality.

The µCMM provides exceptional geometric accuracy by integrating multiple optical 3D measurements. It captures fine surface details on large components and precisely aligns these measurements. It can measure a wide range of surfaces, including common industrial materials and advanced composites such as plastics, PCD, CFRP, ceramics, chrome, and silicon.

With single-button controls and an ergonomic controller, the µCMM ensures easy operation. Its air-bearing axes with linear drive deliver wear-free, fast, and precise measurements, making it ideal for reliable, long-term use in production environments.

Why Optical Dimensional Metrology?

Optical dimensional metrology offers a non-contact, highly accurate, and versatile solution for precise measurement and quality control in manufacturing environments. It leverages advanced optical technology to provide detailed and reliable measurement data in real-time, enhancing efficiency and accuracy across various industries.

Benefits of the optical CMM Machine

The µCMM from Bruker Alicona allows you to measure complex components and geometries with extremely tight tolerances in high accuracy. Thanks to the innovative Advanced Focus-Variation technology, fast, non-contact, and high-resolution 3D measurements are now easier than ever.

- Unmatched precision: Achieve measurement accuracies in the sub-micron range.

- Fast results: Benefit from rapid measurements without compromising accuracy.

- Multiple measurements: Measure dimension, position, shape and roughness with only one sensor.

- User-friendly: Simplify your measurement process with the intelligent MetMaX measurement technology software.

The µCMM is not only a measuring device but your partner in quality assurance. Trust in Bruker Alicona’s proven technology and sustainably optimize your manufacturing processes.

Optical measurement of precision dies (punches, stamping and bending tools) with the optical cmm machine

Versatile Applications of the Coordinate Measuring Machine CMM

The µCMM is versatile and supports various industries in quality assurance and process optimization. Here are some examples:

- Automotive: Precise measurement of engine components, transmissions, and body parts to ensure the highest quality standards.

- Aerospace: Analysis and measurement of turbine blades, aircraft parts, and other safety-critical components.

- Electronics: Inspection of PCBs, microelectronics components, and other highly sensitive electronic parts.

- Medical Technology: Accurate measurement of implants, prosthetics, and surgical instruments to meet strict medical standards.

Gear shafts

Turbine blades

Electronic plug connections

Knee implants

Optical µCMM & MetMaX: Automated Measurement & Evaluation

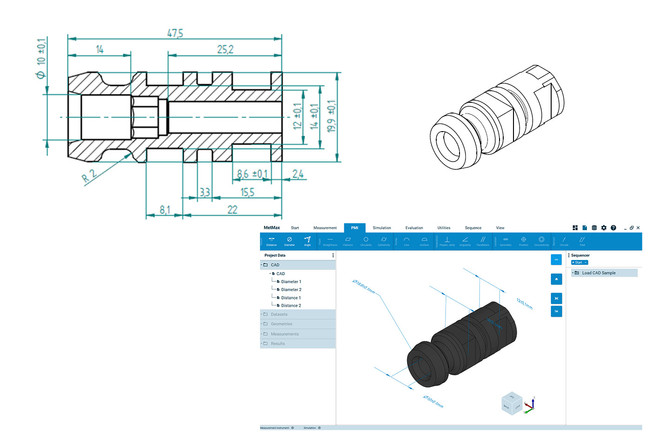

Optimize your manufacturing processes with the optical coordinate measuring machine µCMM from Bruker Alicona. With the smart 3D metrology software MetMaX, it's a breeze: simply upload your part's CAD data, select the desired GD&T or PMI features, and MetMaX takes care of the rest!

MetMaX's user-friendly design empowers users to maximize the measurement system's potential without needing specialized metrology or user knowledge. The expertise for optimal 3D data capture and analysis is built into the software. Enhance the quality assurance of your components and integrate Bruker Alicona's automated metrology into your manufacturing process. Boost your efficiency, save time, and improve your production precision with the automated metrology software MetMaX!

Discover the µCMM’s Full Potential

Ready to explore how the µCMM can transform your manufacturing processes? Download our detailed product folder now to learn all about the benefits and technical specifications of our optical coordinate measuring machine!

dieSonne(6)-2000x857.png)

dieSonne(6)-2000x3000.png)

dieSonne(6)-2000x2000.png)