Un matrimonio logico nella tecnologia dell'automazione

Festo is a leading global supplier of automation technology. Can it be that Festo itself relies on cumbersome, time-consuming and inefficient solutions in quality control? Of course not.

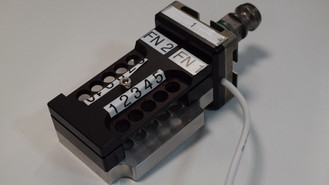

When you talk about a family business, you might think of the small grocery store around the corner. Festo proves that this notion can be an absolute fallacy. On the one hand a third-generation family business, on the other a global player with over 250 subsidiaries in 61 countries and 21,000 employees, Festo manufactures pneumatic and electric control and drive technology. Process and factory automation are Festo's business.

Of course, component quality control has always played a role. However, the inspection process was cumbersome and time-consuming. Until Horst Lang, Head of Global Operative Production Quality, became aware of Bruker Alicona's Focus Variation technology. What used to be laboriously measured with several different systems, the measuring device from Bruker Alicona does independently of time and people with just one sensor.

Read here the whole story of a successful automation marriage and which additional applications were necessary to help Festo achieve the desired measuring process.

Feel free to let us hear your quality assurance requirements as well.