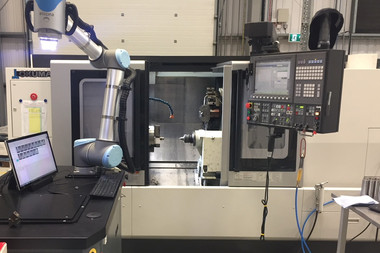

High-resolution geometry measurement with a collaborative robot

Combined with robot systems, robust optical 3D metrology is offering new possibilities for inline optical geometry measurements, enlarging the measurement area beyond a single field of view. Measurements which have been impossible due to light/shade influences, can now be performed by using robots offering high-resolution 3D datasets, even of undercuts. A special algorithm uses the position and angle of the robot tool centre point - which is, in this case, the focus point of the measuring system for the pre-alignment of the different 3D datasets before the final stitching. Another algorithm is used to improve the overall accuracy through the dataset alignment. This method is important for big samples with complex geometries. The measurement examples presented in this paper aim to examine and minimize the uncertainty of optical 3D metrology combined with a robot.

Authors: Riedl Matthias; Lankmair Thomas; Danzl Reinhard. High Speed Machining. Advances in Manufacturing Technology, 15th International Conference 2019.

Difference measurement of two 3D datasets. The angle between both datas is roughly 89,8°.