Closed Loop for Cutting Edge Preparation

with Optical 3D Metrology

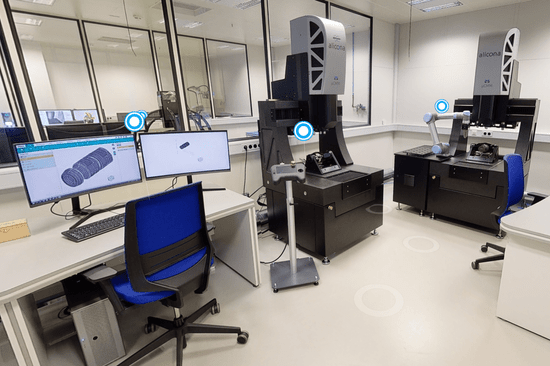

Visit us at GrindingHub from May 14th to 17th in Stuttgart and experience the innovations in the field of cutting edge preparation up close! Together with the world's leading specialist in honing and superfinishing technology, Nagel Maschinen- und Werkzeugfabrik GmbH, we present the automated cell for cutting edge preparation, NaPrep. The integrated quality assurance, based on optical 3D metrology from Bruker Alicona, enables automatic process correction, providing a closed loop.

Dive into the world of cutting edge preparation and find out how NaPrep in combination with optical 3D measurement technology can transform your manufacturing processes and offer you maximum precision and efficiency. We look forward to welcoming you at our booth D20, Hall 8!

Time left to GrindingHub 2024

Take a sneak peek of our booth highlights

NaPrep for the selective and defined rounding of cutting edges

Selective and defined cutting edge rounding offers numerous well-known advantages: It reduces the risk of chipping, increases the quality and tool life and improves both chip removal and surface quality.

In NaPrep, NAGEL combines process automation and quality assurance from Bruker Alicona in one cell. The EdgeMaster technology not only enables high-resolution and robust measurements, but also offers intelligent evaluation software based on future VDI standards.

The automated measurement results can be seamlessly integrated into the process, enabling automated control within the cell.

NaPrep: Automated cell for cutting edge preparation with included quality assurance from Bruker Alicona; (c)Nagel

Bruker Alicona's measurement technology is a market leader and much more accurate than tactile methods.

Take Your Manufacturing Process to the Next Level

Automated Round Tool Measurement

At GindingHub, we will also be showcasing our latest software feature, Round Tool Alignment. This will take automation in the area of round tools to a whole new level. The user plans the measuring positions of interest for edge rounding directly on the CAD of the tool. Once the tool has been clamped, the measurement starts. The automated routine of the sensor recognizes the orientation of the tool and aligns it with the CAD data. This is followed by the 3D measurements and the evaluation of the edge rounding according to the positions defined on the CAD.

Highest Quality for Your Cutting Tools

Discover the Bruker Alicona portfolio for quality assurance of cutting edges. The Focus-Variation technology used sets standards not only in terms of edge rounding, but also in the measurement of:

- real edge geometry,

- sharpness,

- the roughness of the rake face,

- and over 50 other edge parameters.

FocusX

The new FocusX delivers state-of-the-art measurement technology in a smart and affordable package. The FocusX measures even steep flanks and acute angles with just one single optical sensor. Even large quantities are no challenge for the fastest and most versatile optical 3D measuring device on the market.

dieSonne-041.jpg)

InfiniteFocus G6

The InfiniteFocus G6 is a universal optical 3D measuring device for form and surface roughness measurements. The measuring system works in the µm and sub-µm range and delivers precise results regardless of the size, material, geometry, weight or surface quality of the component.

dieSonne-161.jpg)

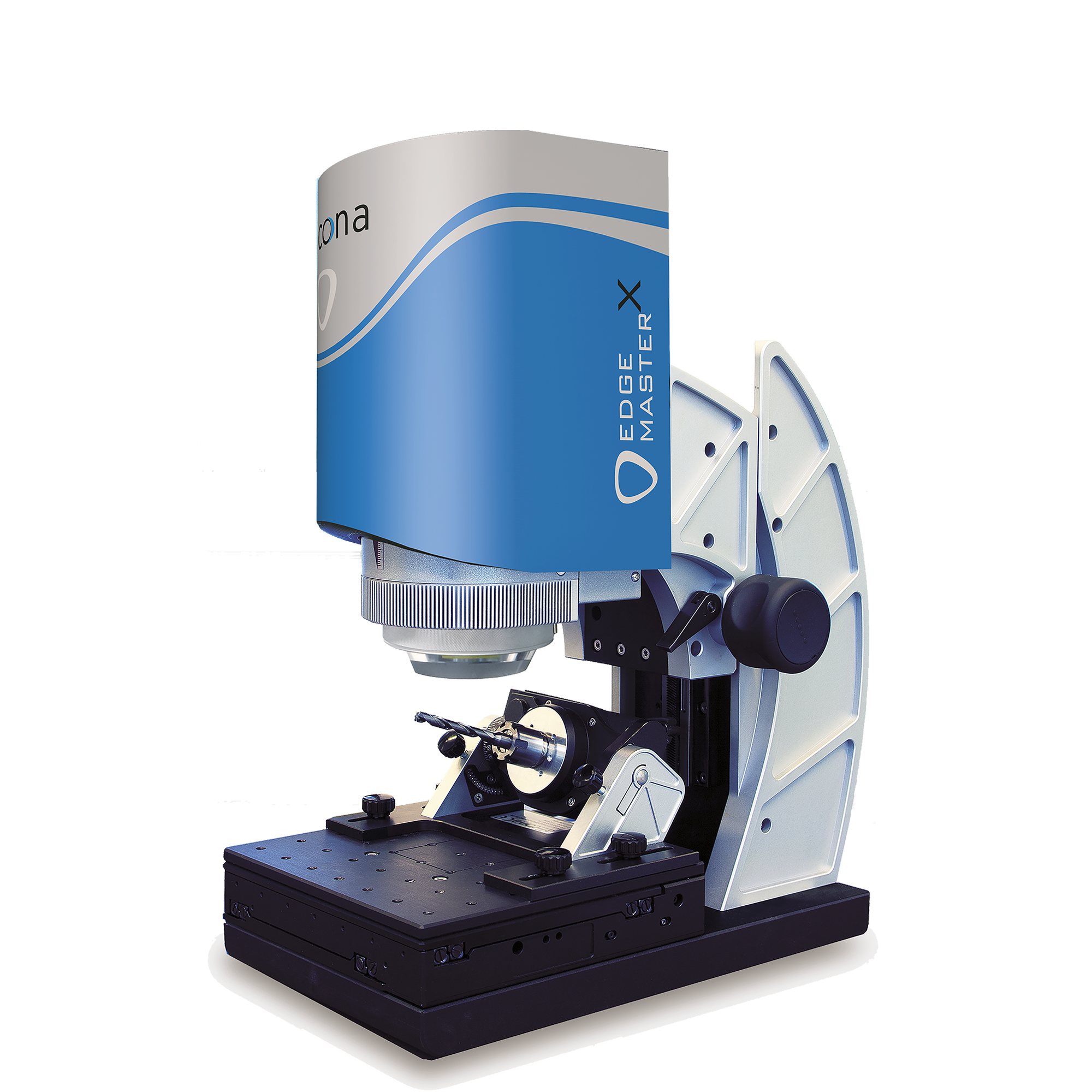

EdgeMasterX

Achieve unparalleled precision with our EdgeMasterX, perfect for high-resolution, fully automatic measurement of tool cutting edges in any production setting. Focus-Variation technology delivers consistent, reliable results, even in challenging conditions such as vibrations, ambient light, and temperature fluctuations. Experience accuracy you can trust, every time.

MetMaX: Elevate your measurement planning with intelligent operator software

The MetMaX operator software sets new standards in usability. Users specify measurements already on the CAD model of a component. A Digital Twin combined with a virtual measurement simulation enables safe operation of the measuring instrument.

Experience our optical measuring solutions

3 reasons why you should visit us

Bring your component &

we measure together on site.

Find your ideal measurement solution.

Get to know us in person.

dieSonne-145.jpg)