What is Inline Measurement Technology?

Inline measurement technology (also called automatic measurement technology) refers to integrating measurement systems directly into the production process. This technology makes it possible to record and use measurement data continuously and in cycles within the production line. The aim is to guarantee product quality and control production processes in real time. Continuous monitoring means that faults can be identified and rectified immediately. This prevents them from affecting the entire production process.

dieSonne-145.jpg)

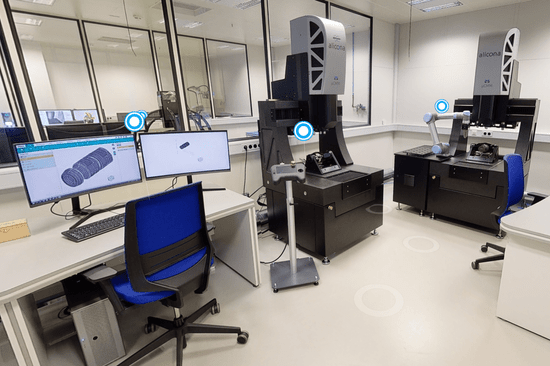

Inline measurement with the InfiniteFocus G6 optical measuring device

Why inline measurement technology?

Maximize your efficiency and quality

Precision is crucial in modern production. Here are some of the main advantages of inline measurement systems:

- Early fault detection: Inline measurement technology enables the immediate detection of faults and deviations. This allows you to take immediate action to avoid quality losses and rejects.

- Continuous process control: An automatic measurement system gives you precise and continuous monitoring of production processes, resulting in more stable production and less downtime.

- Cost savings: You avoid expensive rework and rejects by detecting deviations in good time. Inline measurement systems help to use resources more efficiently and reduce production costs.

- Real-time data: Use up-to-date data to immediately adjust and optimize your production processes. The immediate feedback improves decision-making and process stability.

Cobot (collaborative robot combined with an optical 3D sensor) for inline measurement of turbine engine components

Areas of application for inline measurement

Inline measurement is used in many industries, including:

- Automotive industry: Monitoring of car body and engine components.

- Aerospace: Precision measurement of components.

- Medical technology: Ensuring the high quality requirements of medical devices.

- Electronics: Inspection of printed circuit boards and other electronic components.

Bipolar plates

Turbine blades

Knee implants

Electronic plug connections

How it works

Inline measurement systems are integrated directly into the production process, often between different production steps or at critical points on the production line. The systems measure continuously and precisely, with the data being analyzed immediately. This enables a rapid response to deviations and ensures the high quality of the end products.

Our inline solution for your production

We offer you tailor-made inline measurement technology solutions that optimize your production processes and ensure your product quality. Find out how you can revolutionize your production line with state-of-the-art measurement technology.

Maximize your added value with the latest inline measurement technology!

Increase your efficiency and ensure the quality of your products with inline (automatic) measurement technology from Bruker Alicona. Visit our website to learn more about our innovative solutions and how we can help you achieve your production goals.

.jpg)

The FocusX with the intelligent automated metrology software MetMaX for inline measurement.