What is Real3D technology?

Real3D technology offers

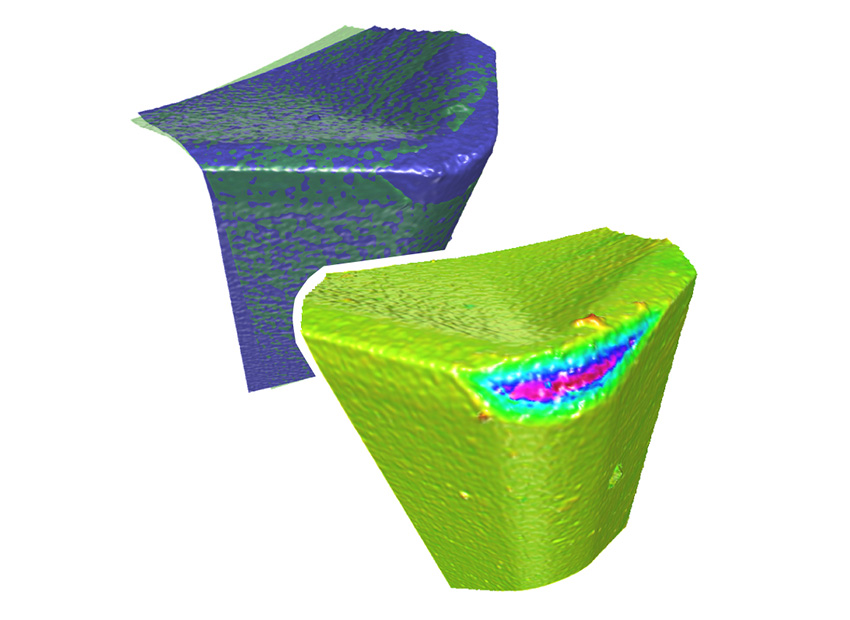

- complete geometry measurements of complex component geometries,

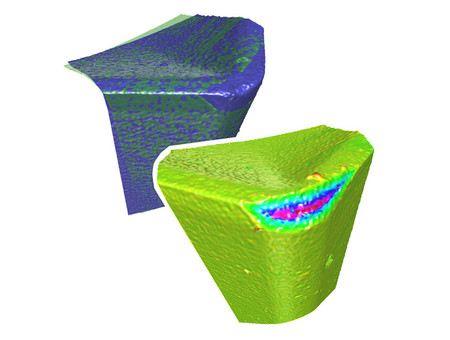

- analysis of even complex profiles and the measurement of flat and curved components and

- verification of form deviations

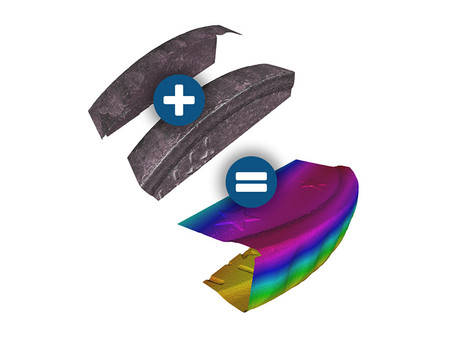

By creating a digital twin of the component, target-actual comparisons to CAD data are possible.

How does Real3D work?

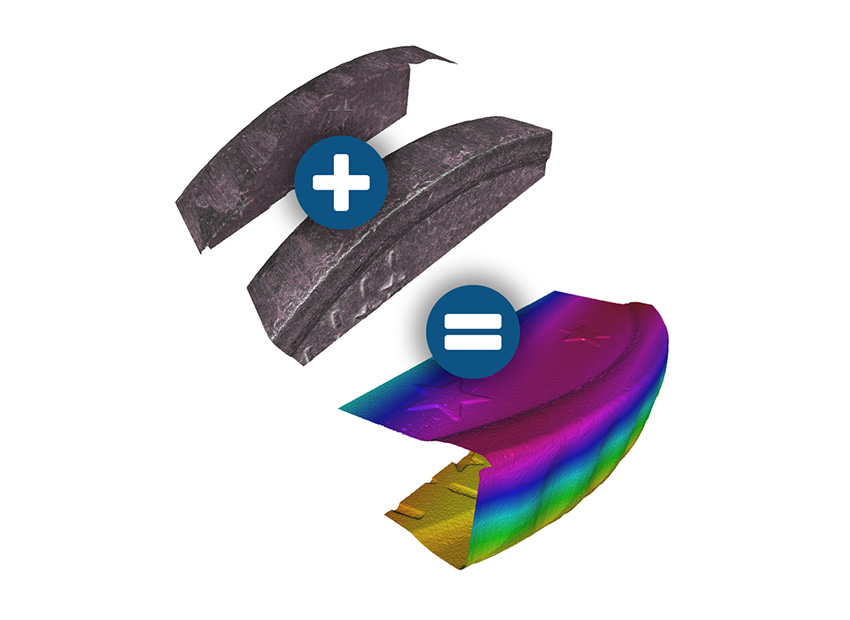

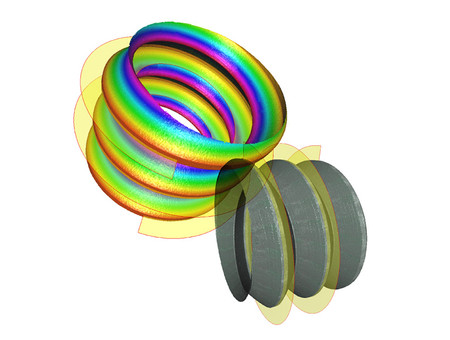

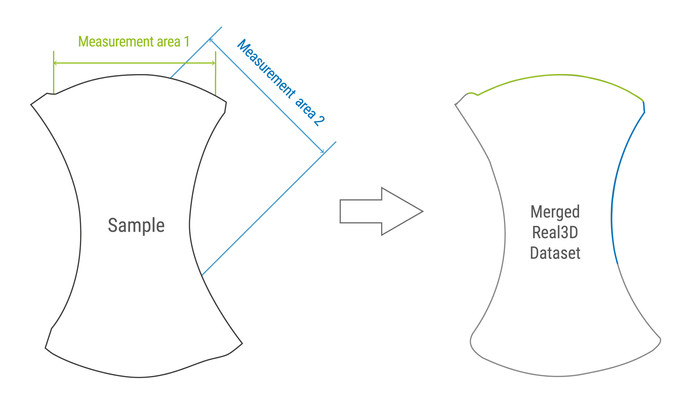

The component is measured at various rotation and tilt angles. Based on the registered true color information of each measurement point, the single measurements are transformed into a joint coordinate system. The single overlapping measurements are then precisely merged into a complete 3D data set.

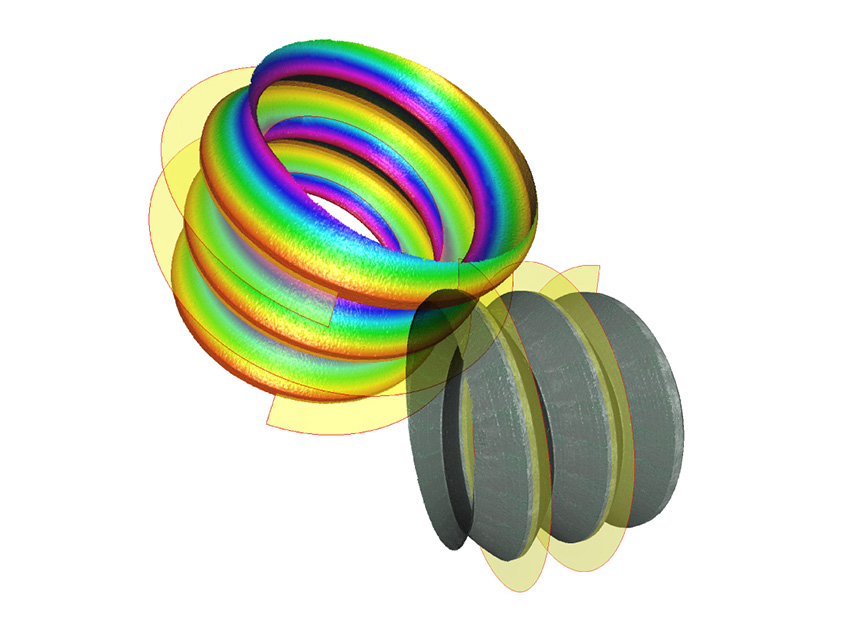

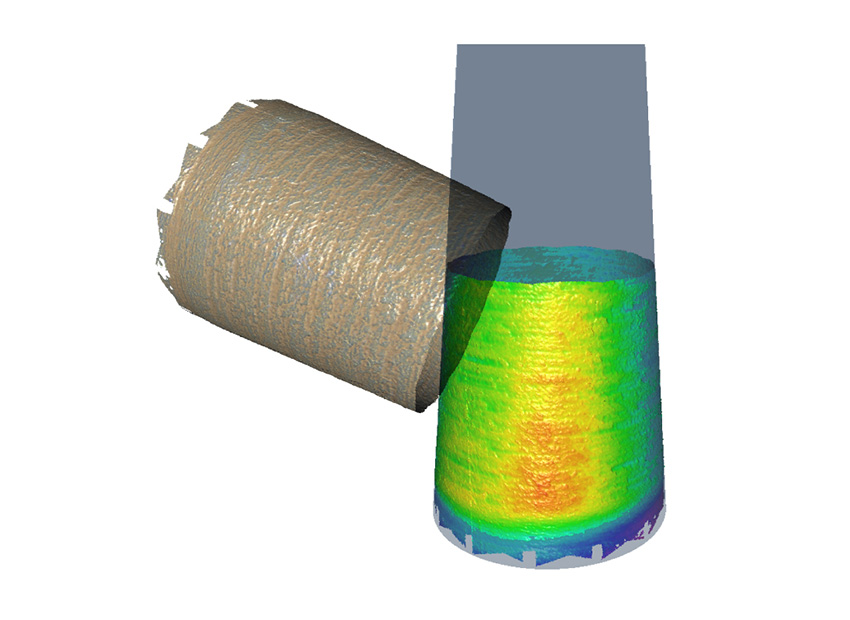

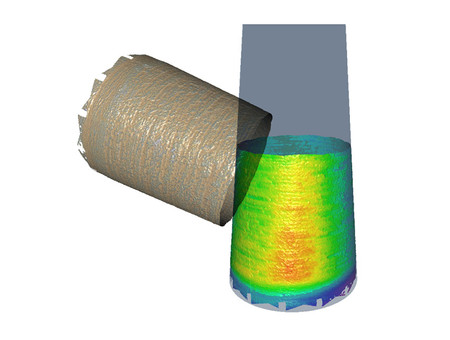

Various types of full form measurement with Real3D

Real3D enables measurements of form and roughness from numerous perspectives. These single measurements are then automatically merged into a full 3D data set. As a result, users obtain a visualization of the component from different angles as well as measurements of contour, difference and form. Thanks to high-precision and calibrated rotation and tilt axes, measurements are repeatable and traceable too.

Real3D Rotation Units

Bruker Alicona offers several options for Real3D measurements. The AdvancedReal3DUnit and the Real3DUnitX are equipped with a motorized tilting axis and motorized rotation axes, whereas the Real3DRotationUnit is based on motorized axes and a manual tilting axis. All models are used for full-field measurement of typically round tools.The fully motorized versions can also be used for the automatic measurement of punching tools, the measurement of micro-holes and reverse engineering. In addition, users can measure the main and secondary edges of their drill, milling cutter, etc. in just one measurement run.

Real3DRotationUnit

available for: InfiniteFocusSL, EdgeMasterX

AdvancedReal3DUnit

available for: µCMM, InfiniteFocus G6

Real3DUnitX

available for: FocusX