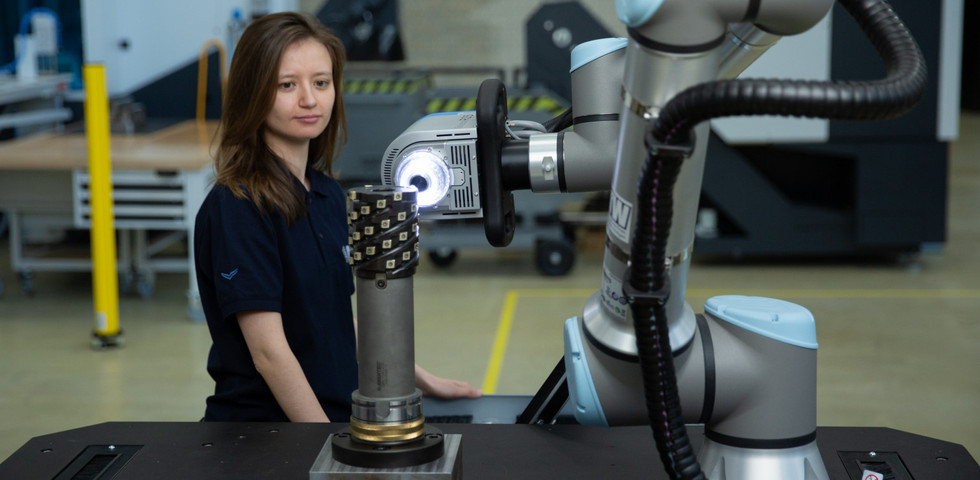

Verify surface quality & dimensional accuracy of small features on large components

Our cobots consist of a collaborative 6-axis robot and a stable optical 3D measurement sensor, which provides repeatable and traceable measurements in high resolution even under production conditions. Handling, programming and measurement of taught-in measurement series do not require any previous metrology knowledge.

This makes cobots ideal for verifying the surface finish and dimensional accuracy of workpieces in existing production environments. Users check the surface quality and dimensional accuracy of small features on large components.

Technical specifications

| Robot type | UR-10 | |

| Specimen radius | 1300 mm | |

| Safety | collaborative - stops at collision with an object; certified by TÜV Nord and TÜV Süd | |

| Axes | 6 rotating joints | |

| Repeatablitiy | +/- 0.1 mm | |

| Sensor | IF-SensorR25 - travel range in Z 26 mm motorized - LED travel ring light with 24 segments - 126 mm x 153 mm x 202 mm (W x D x H) | |

| Mass | approx. 30 kg |

More measuring systems of the Cobot series

DiscCobot: Evaluation of break edges

The DiscCobot is used for the quality assurance of large rotationally symmetric components up to 120 kg. In particular, the Cobot is applied in the standardized evaluation of edge breaks. By verifying minimal radii, it prevents sharp edges that can, in the worst case, compromise aircraft safety. The DiscCobot is used in the aircraft industry for the measurement of e.g. turbine housings and turbine discs as well as in the tool industry e.g. for the cutting edge measurement of saw blades.

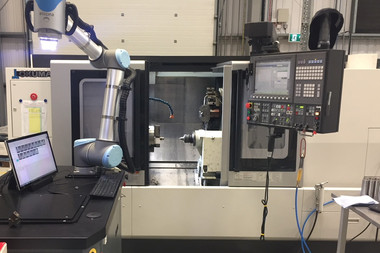

TurbineCobot: High-resolution and automatic measurement of micro-structured surface features

The Turbine Cobot is used for the automatic measurement of break edges on turbine cases. Up to 500 measuring positions are taught-in and measured automatically.

CompactCobot: Universal solution for industrial quality assurance

Whereas the existing TurbineCobot and DiscCobot are application-specific solutions for the tooling and aerospace industry, the new CompactCobot is a universal solution applicable to all industries to verify surface state and dimensional accuracy of also large components.