How optical 3D measurement technology can help to identify ideal tool and machining parameters

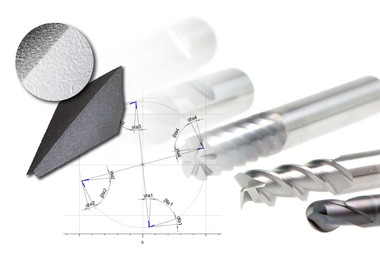

High-end tools with outstanding performance and life-time are essential in manufacturing technology. Users of drills, milling cutters and all sorts of round tools often complain about edge defects, rapid wear, long machining times or unsatisfying results on the workpiece. Testing and constant measuring in research and production is the only solution for manufacturers to produce cutting tools according to the ever-increasing customer demands on tolerances and performance. The following whitepaper "Are your cutting tools competitive” shows how optical 3D measurement technology can help to identify ideal tool and machining parameters and thus meet customer requirements.

Learn more about...

- Challenges faced by manufacturers

- The impact of edge geometry, edge chipping and roughness on tool performance and life-time

- How dimensional accuracy and surface finish can be measured with one single system

How to identify the ideal tool & machining parameters with optical 3D metrology