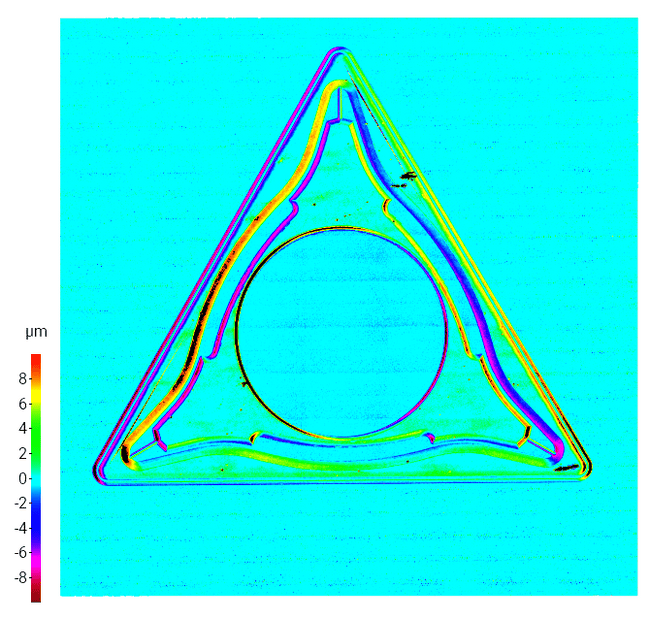

3D inspection of high-precision machined components & a knee implant

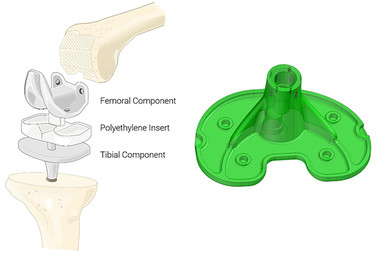

The following measurement report showcases two applications utilizing the most versatile optical measurement device in its class. FocusX is an advanced measuring system specifically designed to handle components with high-gloss surfaces, steep flanks, and complex shapes, making it an ideal solution for the 3D inspection of polyethylene parts of a knee implant. The roughness measurement on FocusX is designed to be particularly user-friendly and guarantees quick and ISO-compliant results. With its intuitive interface, FocusX eliminates the need for specialized knowledge, ensuring efficiency from the get-go.

Also, discover the unprecedented versatility of FocusX in the 3D inspection of dimension, position, shape, and roughness of high-precision machined components, such as those from Kern Precision. The Vertical Focus Probing technology facilitates the lateral probing of workpieces and enables the measurement of holes and bores with a diameter-to-depth ratio of 1:3 to 1:10 - all with just one optical sensor.

FocusX offers automated, traceable, and repeatable measurements, ensuring the utmost accuracy and reliability in the evaluation of complex components.

3D data of a milled & laser-machined component from machine tools