Reach the next level of quality assurance

with optical 3D metrology

Are you interested in exploring the power of optical 3D metrology and the innovative possibilities offered by Focus-Variation technology? If so, we have great news for you! We are happy to invite you to our exclusive Demo Workshop from October 16-17, 2024 at OTEC Precision Finish US, North Kingston, Rhode Island.

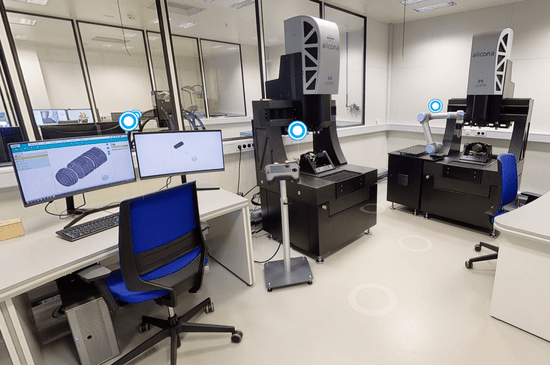

At our workshop, you will have the unique opportunity to witness firsthand the transformative potential of optical 3D metrology. Our non-contact measuring systems are designed to deliver fast, precise, and reliable measurements, making us the ideal partner for your metrology needs.

WHY ATTEND...

- Stay at the forefront of technological advancements and gain a competitive edge in your industry.

- Learn how optical 3D metrology can significantly improve your measurement processes, leading to enhanced efficiency and productivity.

- Discover the transformative potential of Focus-Variation technology and how it can revolutionize your quality assurance procedures.

- Engage with our team of experts and get personalized solutions for your specific metrology challenges.

Join our exclusive live-sessions!

Our metrology experts will present relevant optical 3D measurement solutions and answer your questions in exclusive live-sessions. Don´t forget to bring your samples (components, tools, etc.) to measure!

Discover the new FocusX

OTEC Stream Finishing Machine

Stream Finishing (SF) technology is an advanced mass finishing method where workpieces are clamped and lowered into a rotating container filled with grinding or polishing medium. The combined motion of the medium and the independent rotation of the workpiece achieves extremely smooth surfaces, with values as fine as Ra 0.01. SF offers short finishing times, easy automation, and highly consistent results.

Distinct for its powerful processing forces, SF technology allows for faster and more selective material removal than other finishing systems. It is ideal for applications requiring exceptional surface quality in small geometries, such as deburring, polishing, smoothing, and edge rounding of cutting tools. SF machines excel in finishing stamping, forming, and cutting tools, as well as automotive and aerospace components.

FocusX

Optical coordinate measuring machine to measure tight tolerances

The first purely optical micro-coordinate measuring machine on the market can measure extremely tight tolerances in high accuracy, combining advantages from both tactile coordinate measuring technology and optical surface measuring technology. Dimension, position, shape and roughness of your components are measured with only one optical sensor!

Reserve your personal time slot

OTEC US

44 Cross Park Ave, North Kingstown, RI 02852

OTEC US on Google Maps

Day 1 | October 16, 2024

Group 1 | 09:00 am - 10:30 am

Group 2 | 10:30 am - 12:00 pm

Group 3 | 12:30 pm - 02:00 pm

Group 4 | 02:00 pm - 03:30 pm

Group 5 | 03:30 pm - 05:00 pm

Day 2 | October 17, 2024

Group 1 | 09:00 am - 10:30 am

Group 2 | 10:30 am - 12:00 pm

Group 3 | 12:30 pm - 2:00 pm

Group 4 | 02:00 pm - 03:30 pm

Group 5 | 03:30 pm - 05:00 pm

OTEC Enhances Machine Reliability and Component Quality with Bruker Alicona Optical 3D Metrology

Smoothing, Rounding, Deburring: How Metrology Increases Efficiency

OTEC Präzisionsfinish has relied on Bruker Alicona's Focus-Variation technology for over a decade to enhance machine reliability and component quality. Witness the integration of in-line optical metrology in OTEC's new mass finishing machine, aimed at boosting quality assurance. Soran Jota, Managing Director at OTEC, discusses these innovations with Urban Muraus, General Manager at Bruker Alicona.

Discover the Various Applications of FocusX

Have you ever tried to measure the dimension, position, shape, and roughness of a milled and laser-machined component from machine tools? Learn how the Vertical Focus Probing technology allows to laterally probe the sides of the workpiece, enabling also the measurements of holes and bores with a diameter-to-depth ratio of 1:3 to 1:10.

You want to explore more applications with FocusX? Dive into our measurement report!

More to discover: ??

Register now for your personal demo

Lorem ipsum

3 reasons why you should visit us

Bring your component &

we measure together on site.

Find your ideal measurement solution.

Get to know us in person.

dieSonne-044-2000x857.jpg)

dieSonne-057-300x200.jpg)